Why Your Serial Devices Fail on Ethernet Networks (And How to Fix It)

Serial to Ethernet Converter: Fix Device Network Failures

If you’ve ever tried connecting an old serial device to a modern Ethernet network and thought, “This should be simple,” you’re not alone. In reality, many industrial teams face frequent connection drops, data loss, or complete communication failure when legacy serial devices meet IP-based networks.

The good news? Most of these issues are fixable. Let’s break down why serial devices fail on Ethernet networks and how you can fix them the right way.

Why Serial Devices Struggle on Ethernet Networks

Serial communication (RS232, RS485, RS422) was designed for short-distance, point-to-point connections. Ethernet networks, on the other hand, are built for packet-based communication over IP. When you mix the two without the right setup, problems start to show.

Here are the most common reasons failures happen:

1. Protocol Mismatch

Serial devices speak protocols like Modbus RTU or proprietary formats, while Ethernet networks rely on TCP/IP. Without proper protocol translation, data packets either get corrupted or never reach the device.

Fix: Use a reliable serial to ethernet converter that supports protocol conversion like Modbus RTU to Modbus TCP and handles packet framing properly.

2. Wrong Converter or Low-Quality Hardware

Not all converters are built for industrial environments. Cheap devices may work in labs but fail under electrical noise, vibration, or continuous operation.

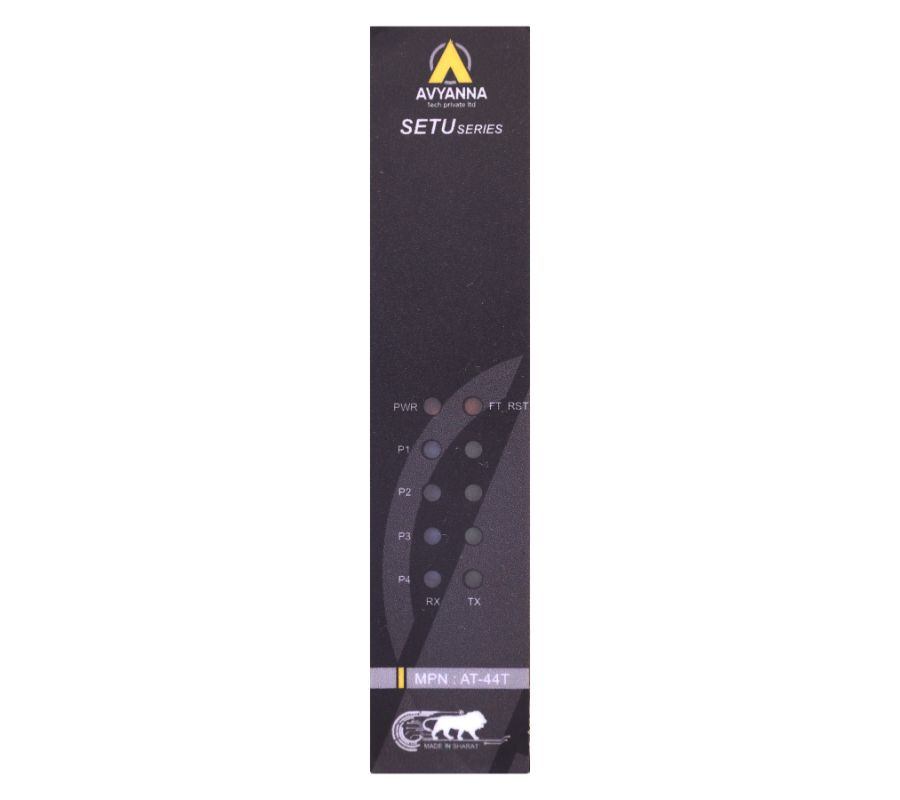

Fix: Choose an industrial-grade serial to ethernet converter or device server designed for 24/7 uptime, surge protection, and stable performance in control panels and plant floors.

3. Baud Rate & Serial Settings Mismatch

Even a small mismatch in baud rate, parity, stop bits, or flow control can cause data loss or unstable communication.

Fix: Double-check serial parameters on both the device and the converter. Match:

- Baud rate

- Data bits

- Parity

- Stop bits

This simple step solves a surprising number of “mystery” failures.

4. Network Latency & Timeouts

Serial communication expects near-instant responses. Ethernet networks introduce latency, which can cause timeouts in PLCs, SCADA, or monitoring software.

Fix: Configure timeout values properly in your SCADA/PLC software and use converters that buffer data intelligently to handle network delays.

5. IP Conflicts & Network Configuration Errors

Incorrect IP settings, firewall blocks, or NAT issues often stop serial devices from appearing on the network.

Fix:

- Assign static IPs to your converter

- Open required ports

- Check firewall rules

- Ensure the converter is on the same subnet as the monitoring system

6. Electrical Noise & Grounding Issues

Serial lines are sensitive to noise, especially in industrial environments with motors and heavy machinery. This can lead to random data drops.

Fix: Use shielded cables, proper grounding, and industrial communication devices that provide electrical isolation.

How to Fix Serial-to-Ethernet Issues the Right Way

Instead of patching problems one by one, the most reliable solution is using a professional serial device server or gateway that is built specifically for industrial networking.

A properly configured serial-to-IP solution helps you:

- Convert serial protocols to Ethernet cleanly

- Stabilize communication over long distances

- Centralize monitoring and diagnostics

- Integrate legacy devices into modern networks without replacing equipment

This is where an industrial serial to ethernet converter or Modbus gateway makes a real difference, especially for factories, utilities, and automation projects running mixed legacy and modern systems.

Real-World Example

A manufacturing plant tried connecting old RS485 energy meters directly to their Ethernet network using basic converters. They faced:

- Random disconnections

- Data gaps

- Frequent manual resets

After switching to an industrial serial device server with proper Modbus gateway support, the system became stable, and monitoring data became reliable in real time.

Conclusion

Serial devices don’t fail because they’re outdated; they fail because they’re forced into modern networks without the right bridge in between. With the right configuration and a reliable serial to ethernet converter, legacy equipment can work smoothly in today’s Ethernet-based automation systems.

If you’re struggling with unstable serial-to-Ethernet communication, it’s often not the device that’s the problem; it’s the integration approach.

[email protected]