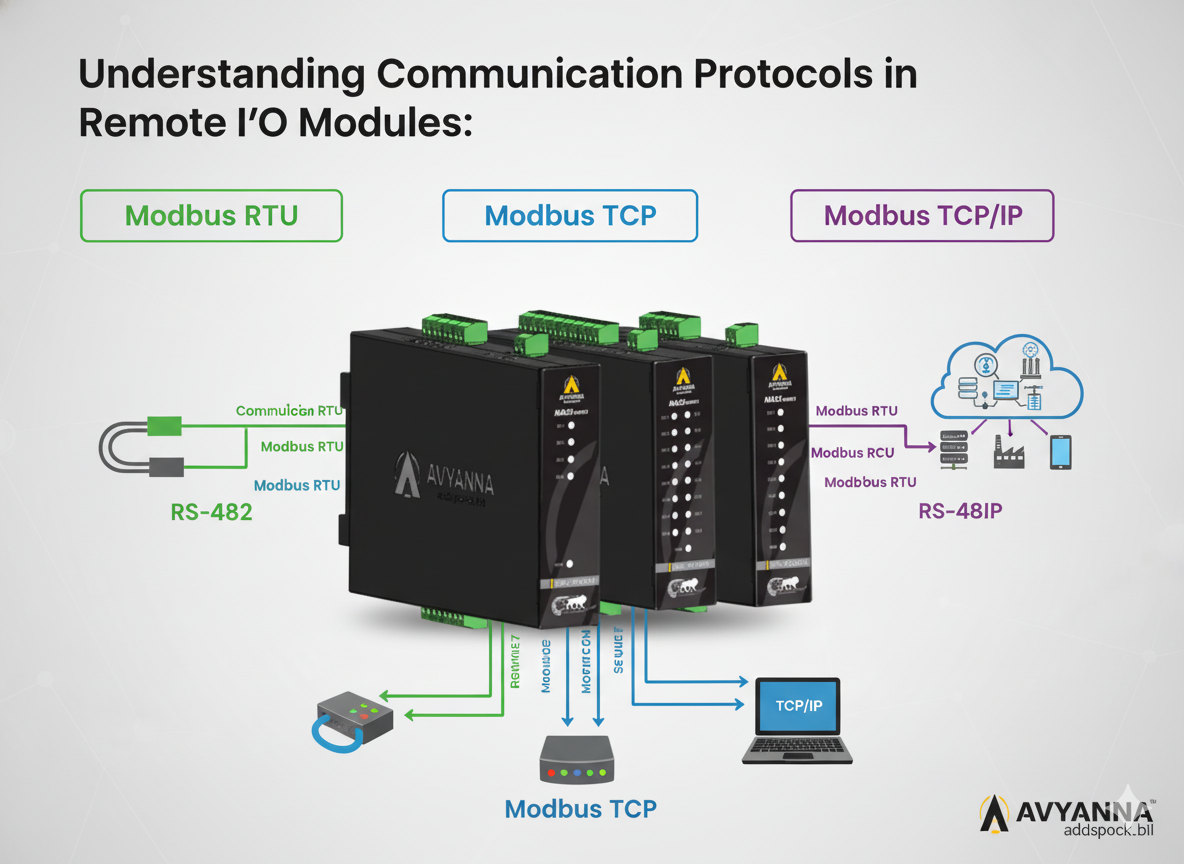

Understanding Communication Protocols in Remote I/O Modules: Modbus RTU, Modbus TCP, and Modbus TCP/IP

In modern industrial automation, seamless data exchange between devices is the foundation of efficiency. Remote I/O Modules play a critical role in connecting sensors, actuators, and control systems, bridging the gap between field devices and supervisory systems like PLCs or SCADA.

But what truly enables this communication?

It’s the communication protocols, and among the most widely used are Modbus RTU, Modbus TCP, and Modbus TCP/IP.

Let’s understand how each of these works, where they’re used, and how Avyanna Tech’s Remote I/O Modules leverage them to power industrial connectivity.

What Are Remote I/O Modules?

Remote I/O Modules (Input/Output Modules) are compact devices that collect and transmit data between sensors, actuators, and control systems, often over long distances. They help industries expand I/O capacity without complex wiring, reducing cost, downtime, and installation effort.

At Avyanna Tech, our Ethernet and Serial Remote I/O Modules are designed to deliver reliable, high-speed data communication across various industrial environments from factory floors to process automation systems.

1. Modbus RTU – The Reliable Serial Protocol

Modbus RTU is one of the oldest yet most trusted communication protocols in industrial automation. Operating over RS-485 serial lines, it uses a master-slave structure where a single master device (like a PLC) communicates with multiple slaves (I/O modules or sensors).

Key Features of Modbus RTU:

- Simple and cost-effective for short-distance serial communication

- Ideal for legacy systems and compact automation setups

- Low bandwidth requirement and robust noise immunity

Avyanna Tech Modbus RTU Remote I/O Modules:

- 8-ch Analog Input with Modbus RTU (MPN: AT-11013 / AT-11023)

- 4 Analog Output – 4 Digital Input with Modbus RTU (MPN: AT-13241)

- 7-ch RTD Module with Modbus RTU (MPN: AT-15002)

- 8-ch Thermocouple Input Module with Modbus RTU (MPN: AT-16003)

- 8 Digital Input – 8 Digital Relay Output with Modbus RTU (MPN: AT-13433)

- 8 Digital Relay Output Module with Modbus RTU (MPN: AT-14003)

- 16 Digital Input Module with Modbus RTU (MPN: AT-13005)

These modules are perfect for environments where stable, point-to-point serial communication is preferred, such as temperature monitoring, analog signal control, or small process stations.

2. Modbus TCP – High-Speed Ethernet Connectivity

As industries evolved toward smart factories and Industry 4.0, Ethernet-based communication became essential. Modbus TCP brings the simplicity of Modbus into the world of Ethernet networks, offering faster communication and greater flexibility.

Key Advantages of Modbus TCP:

- Faster data transmission over standard Ethernet cables

- Easy integration with PLCs, HMIs, and SCADA systems

- Supports multiple masters, allowing greater scalability

- No special converters required; uses existing Ethernet infrastructure

Avyanna Tech Modbus TCP Remote I/O Modules:

- 8-ch Analog Input with Modbus TCP (MPN: AT-21013 / AT-21023)

- 4 Analog Output – 4 Digital Input with Modbus TCP (MPN: AT-23241)

- 7-ch RTD Module with Modbus TCP (MPN: AT-25002)

- 8-ch Thermocouple Input Module with Modbus TCP (MPN: AT-26003)

- 8 Digital Input – 8 Digital Relay Output with Modbus TCP (MPN: AT-23433)

- 8 Digital Relay Output Module with Modbus TCP (MPN: AT-24033)

- 16 Digital Input Module with Modbus TCP (MPN: AT-23005)

These modules enable faster and more reliable communication for distributed control systems, real-time monitoring, and data logging applications.

3. Modbus TCP/IP – Scalable and Network-Ready

Modbus TCP/IP builds upon Modbus TCP by integrating IP-based addressing, allowing devices to be accessed anywhere across a local or global network. This makes it a powerful solution for large-scale automation systems where centralized control and cloud connectivity are essential.

Why Choose Modbus TCP/IP?

- Remote access over LAN/WAN or the Internet

- Scalable for multi-site and cloud-integrated systems

- Ideal for smart industries and IoT-based automation

Avyanna Tech TCP/IP Remote I/O Modules:

- 12 Digital Input – 8 Digital Output Module with TCP/IP (MPN: AT-23400)

- 4 Digital Input Module with TCP/IP (MPN: AT-23000)

With Modbus TCP/IP, you can seamlessly integrate your plant-floor devices with higher-level systems, empowering predictive maintenance, centralized control, and efficient data management.

Choosing the Right Remote I/O Module for Your Application

When selecting a Remote I/O Module, consider:

- Communication type: Serial (RTU) for short distances or Ethernet (TCP/IP) for larger systems

- I/O requirements: Number and type of analog/digital channels

- Compatibility: Ensure protocol compatibility with your existing PLC, SCADA, or HMI

- Scalability: Choose TCP/IP modules if you plan to expand or integrate cloud-based monitoring

Our modular range ensures there’s a perfect fit for every application, from simple control systems to complex industrial networks.

Why Avyanna Tech for Remote I/O Modules?

- Proven expertise in industrial communication technologies

- Wide range of Modbus-compatible I/O modules (RTU, TCP, TCP/IP)

- Reliable performance under harsh industrial conditions

- Easy integration with leading PLCs, SCADA, and automation platforms

- Backed by expert technical support and engineering consultation

At Avyanna Tech, we don’t just supply hardware; we build the backbone of your industrial communication.

Conclusion

Whether you’re modernizing a legacy system or building a connected plant from scratch, understanding how Modbus RTU, Modbus TCP, and Modbus TCP/IP work is key to choosing the right Remote I/O Module.

With Avyanna Tech’s advanced Remote I/O Modules, you get robust connectivity, reliable data flow, and flexibility to scale your automation systems effortlessly.

Explore our full range of products here.

[email protected]