What is Remote I/O Modules: Its Functions, Benefits and Applications

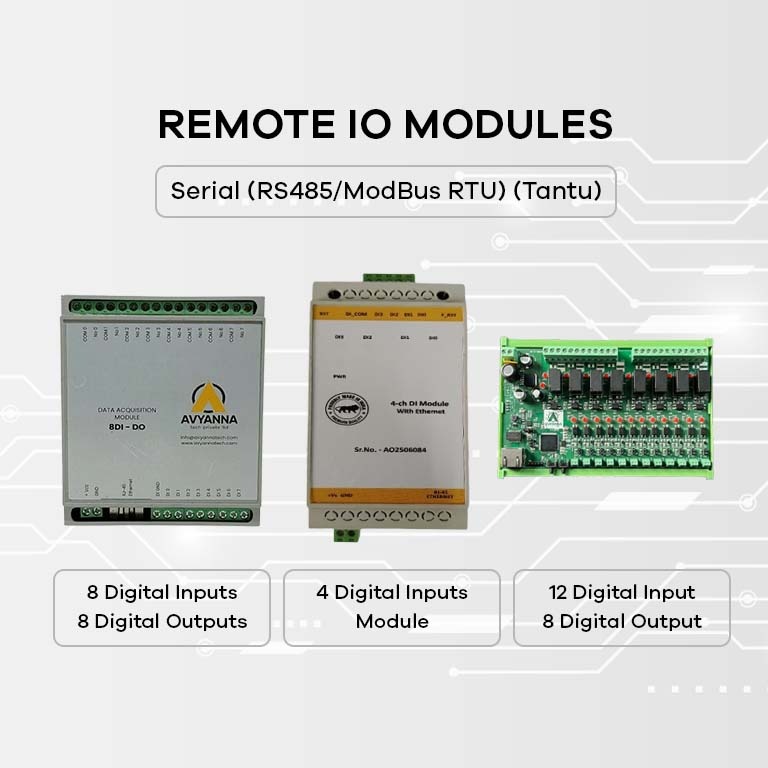

In modern industrial automation, getting accurate, real-time data from field devices is critical. That’s where Remote I/O modules come into play. These devices help collect input and output signals from machines, sensors, and other field instruments—and transmit them back to a central control system. At Avyanna Tech, we provide high-performance Remote I/O modules designed to boost system flexibility, reduce wiring, and simplify expansion. This blog explains how remote I/O works, why it matters, and where you can use it.

Importance and Definition of Remote I/O

Remote I/O modules are devices used to extend the input and output capabilities of a control system across long distances. Instead of routing every wire back to a main controller, remote I/O allows you to place modules closer to the equipment. This reduces installation costs, minimizes signal loss, and improves system response time. In simple terms, remote I/O collects digital or analog signals from field devices and sends them to PLCs, SCADA, or DCS systems through industrial communication protocols.

How Remote I/O Works

Remote I/O modules work by acting as an interface between the field and the control system. Here’s how it functions:

- Sensors or actuators send analog or digital signals to the I/O module.

- The module processes and converts those signals into a protocol like Modbus TCP/IP, Ethernet/IP, or PROFINET.

- These converted signals are transmitted to the controller or central system over Ethernet or serial communication.

- The controller uses this real-time data to make automation decisions or trigger actions.

Avyanna Tech’s remote I/O modules support multiple protocols and offer fast, stable communication even in noisy or harsh environments.

What Is the Difference Between Local and Remote I/O?

The key difference lies in distance and wiring:

- Local I/O modules are located inside the main control panel, directly connected to the PLC.

- Remote I/O modules, on the other hand, are installed near the field equipment and communicate with the main controller via a network.

Remote I/O is ideal for large plants, distributed systems, or applications where equipment is far apart. It reduces cable length, improves scalability, and lowers overall costs. If you want to expand your system without redoing your control cabinet, remote I/O modules are the right choice.

What Is Decentralised I/O?

Decentralised I/O refers to spreading I/O modules throughout the plant, close to the actual field devices. Instead of bringing all wiring back to one central cabinet, you can have multiple I/O stations across the site. This architecture improves efficiency, cuts down on wiring errors, and makes troubleshooting faster.

With Avyanna Tech’s modular remote I/O systems, you can easily scale or reconfigure your setup as your plant grows. These plug-and-play units offer both DIN-rail mounting and easy integration with existing automation networks.

Applications

Remote I/O modules are used across many industries, including:

- Factory Automation – For monitoring sensors, switches, and relays spread across production lines.

- Power Plants – To control and monitor equipment located at remote sites within the facility.

- Water and Wastewater Treatment – For collecting data from pumps, tanks, and valves in large treatment areas.

- Building Automation – For lighting, HVAC, and access control systems.

- Oil & Gas – To connect field instruments over long distances in explosive or hazardous zones.

At Avyanna Tech, our remote I/O modules are designed to perform reliably in tough industrial environments. With wide voltage support, surge protection, and flexible communication protocols, they’re ideal for both new and retrofit projects.

Upgrade Your Industrial Setup with Avyanna Tech

Ready to boost your control system’s flexibility and reduce wiring headaches?

Explore Avyanna Tech’s Remote I/O Modules today and connect with experts to find the best fit for your application.

[email protected]